Looking for a Reliable Stainless Steel Handle Manufacturer? OEM/ODM for Your Business

Oubeehandle is a manufacturer of Stainless Steel Handles and have been in this field for over 15 years. Our products have been sold to Europe, America, Australia, and other countries, resulting in a good reputation among customers.

It is our goal to be the industry’s best stainless steel handle manufacturer. We offer a variety of rust-free products guaranteed to last for years to come. We are an experienced manufacturer of stainless steel handles with a wide selection of products.

Our products are available in OEM and custom designs as well!

With a professional quality control inspection and packaging department, we are able to control all production processes, from die-casting to polishing to surface treatment.

Get Customized Stainless Steel Handle Quote From Us

Finding the best stainless steel handle manufacturer from a large number of stainless steel handle manufacturers can be very challenging. We are one of the leading and reliable companies for all types of Stainless Steel Handles.

We are a professional furniture handle manufacturer specializing in supplying the best quality handles across the globe. Our furniture hardware are made with superior-grade materials, ensuring top-notch durability and reliability.

Our company not only sells products but also provides a full-service advisory from new product development to product assembly since only this way can we ensure our products’ application and add value to our customers. With our experienced and professional working team, we have exported our products to many countries and regions worldwide.

Custom Options for Your Handles (4)

Oubee Handle Advantages (4)

Get your Free Quote for the Best Stainless Steel Handles Today!

If you need to import door pull handles for your business or project, we are the best company to turn to for your pull handle hardware needs.

We are the leading stainless steel handle manufacturer and supplier in China. Our range of Handles includes kitchen, bathroom, and other door handles manufactured using quality raw materials.

We are dedicated to providing customers with quality service and competitive prices.

Our company believes that affordable pricing, correct quality, responsive service, and timelessness are essential ingredients for a successful partnership.

Our company believes that millions of hardware suppliers exist.

Let’s work together for mutual benefit. Get your Free Quote for the Best Stainless Steel Handles Today!

- Oubee Handles By Cases

- Manufacturing

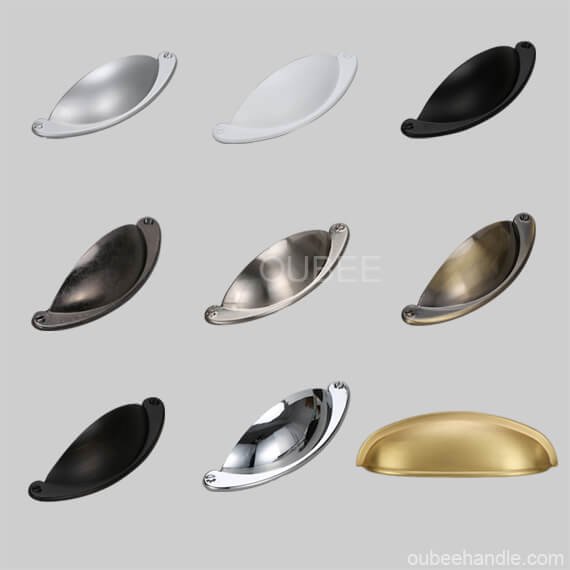

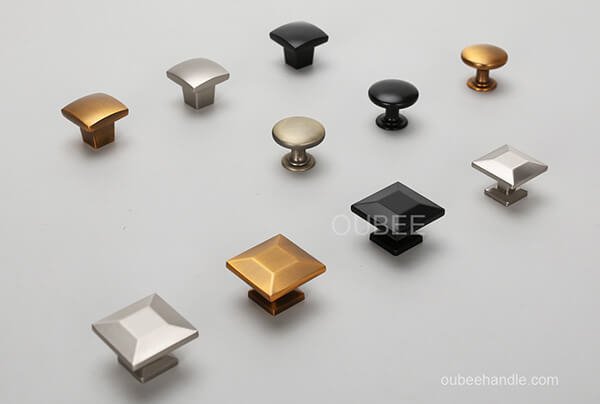

- More Finishes for Your Choose

Choose the right colors for your decoration,OubeeHandle can custom any finishes according to your sample.

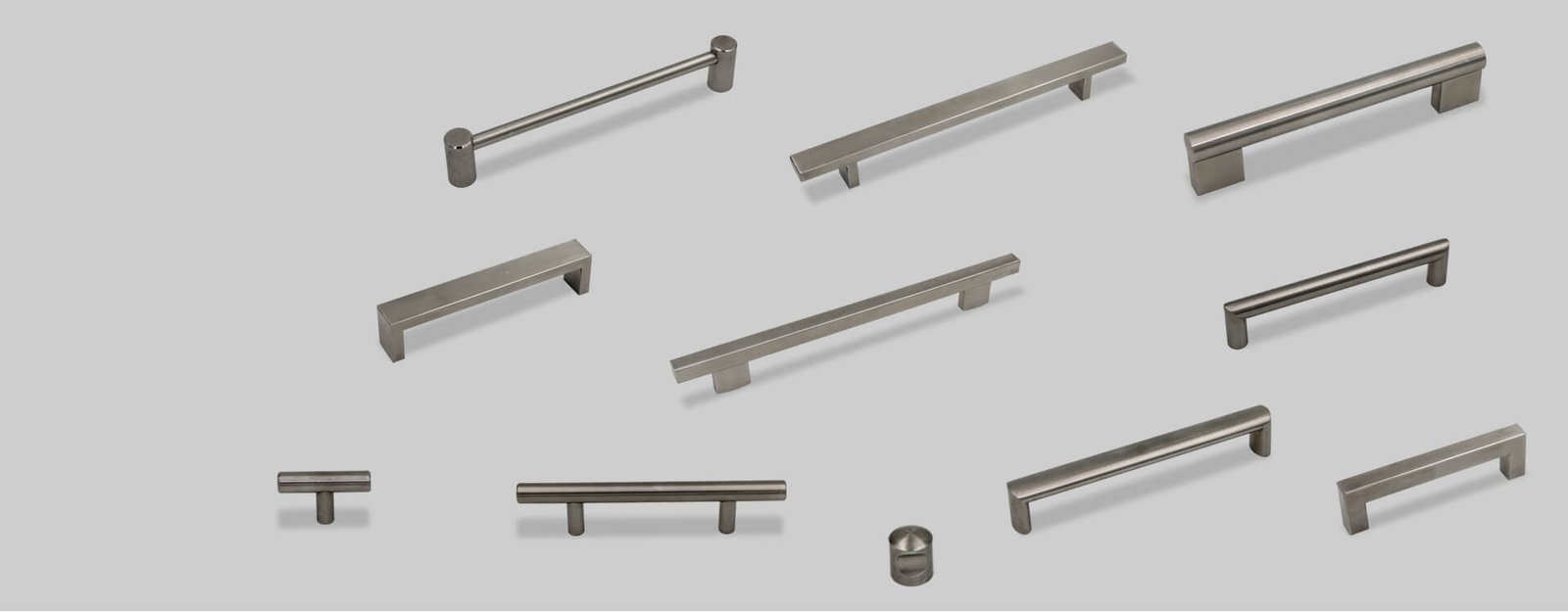

Stainless Steel Handles

In a wide variety of industrial applications, stainless steel handles are frequently used. You can purchase stainless steel handles in various shapes and sizes at our shop, including U-shaped, bridge-shaped, and foldable.

What comes to mind when you hear the term “stainless steel handle”? The most likely answer is robust, durable, and multipurpose pull handles. These are just several reasons why stainless steel pull handles should be used when quality assurance is a priority.

These handles are entirely made of stainless steel, the most frequently used metal for handles. The majority of people have an affinity for stainless steel door handles, stainless steel chest handles, stainless steel cupboard handles, stainless steel industrial handles, stainless steel spring handles, and various stainless steel cabinet handle styles. This is primarily due to these steel materials’ advantageous properties.

Apart from being extremely durable, stainless steel handles are also extremely easy to maintain. Cleaning these stainless steel furniture handles will be a breeze in comparison to other materials. Additionally, stainless steel is attractive without requiring numerous sophisticated finishes. Our company, on the other hand, offers a variety of stainless steel coating options.

Stainless steel handles are extremely versatile. They are available in an array of shapes and designs. It is entirely up to you to select a design that complements the interior of the room. We can even design and manufacture custom stainless steel door handles for you.

Are you thinking about investing in stainless steel handles? First, you must source your stainless steel handles from the most reputable suppliers in China. Here in our OubeeHandle company, we are committed to manufacturing and supplying new steel handles of the highest quality to our customers.

Stainless Steel Handles & Surface Treatment

There is an increasing number of options on the market these days due to the increased demand for handles. As a result, selecting the optimal handle will be more challenging than anticipated. Handles are available in various materials, including aluminum, brass, copper, chrome, iron, nickel, crystal, marble, zinc, glass, pewter, stone, and wood. With this in mind, choosing one that is a good fit for your needs can be pretty daunting.

Each of the materials used in the fabrication of handles is extraordinary. For example, a handle with a high brass content resists tarnishing better. However, if it lacks an adequate amount of metal, it will corrode rapidly.

Copper handles are renowned for their resistance to corrosion and a variety of other problems. It does, however, corrode like brass over time. Despite this, it is an excellent choice because it is necessary for combating impurities such as Clostridium difficult and MRSA. In addition, it has been demonstrated by experts that it is capable of fighting pathogens. Bacteria will quickly vanish from copper surfaces.

A chrome handle, on the other hand, has a gleaming finish. Whether you use a chrome handle on cabinetry or other pieces of furniture, it can elevate their beauty and appeal to new heights. It has a sleek and firm feel that ensures maximum comfort. As a result, you will never have difficulty opening or closing a drawer, wardrobe, or door. Additionally, it is simple to maintain and does not require a lengthy procedure. Cleaning is also quite straightforward. Wipe it clean with a damp cloth.

Each material used in constructing a modern handle is unquestionably advantageous for its intended purpose. Each of these, however, has drawbacks. The advantage here is that additional materials are available to consider. Among them is stainless steel. In addition, as with the others, it has a long history of being renowned for its corrosion resistance. Thus, this material is ideal for individuals who have a corroded handle.

Additionally, stainless steel has high cryogenic toughness, a rapid work hardening rate, a high degree of flexibility, hardness, and strength. Apart from being more durable, it also has a more pleasing appearance than the previous materials. Additionally, it requires minimal upkeep; therefore, you can retain the functionality and aesthetics of the item. Therefore, there is no reason to seek professional assistance.

Without a doubt, stainless steel is an impressive material for everyone. Continue reading if you are interested in learning more. This guide will provide you with information about stainless steel handles.

Nowadays, the market offers a wide variety of stainless steel products. Each is unique in terms of its characteristics and composition. Depending on its chemical composition, stainless steel can be harder, easier to work with, stronger, and magnetic. The following is a brief description of the various stainless steel grades.

What is 201 stainless steel?

The alloy 201 stainless steel is composed of nickel, manganese, and nitrogen. While this is a less expensive option than others, it is not as simple to form. This type of stainless steel is non-magnetic since it is a genuine metal. It is a good source of chromium and nickel. Furthermore, 201 stainless steel is well-known for its low carbon content.

Additional information about type 201 stainless steel handles

Stainless steel type 201 is a mid-range material with a variety of valuable properties. While it is suitable for some applications, it is not recommended for structures exposed to corrosive forces, such as saltwater.

Additionally, the following information is available about this grade:

- Type 201 is a 200 series stainless steel. It was originally developed to conserve nickel. A relatively low nickel content distinguishes it.

- In some instances, type 201 may be used in place of type 301. Despite this, it is less corrosion resistant than its counterpart.

- This grade of stainless steel is non-magnetic. Cold working, on the other hand, can make it magnetic. In addition, type 201 steel contains more nitrogen than type 301 steel, which results in increased toughness and yield strength. This, on the other hand, will occur only at extremely low temperatures.

- Heat treatment does not affect its hardening. It is annealed between 1850 and 1950 degrees Fahrenheit. Following that, rapid cooling of the air and quenching of the water occurs.

- Additionally, it is used in the manufacturing of a variety of household appliances. Apart from sinks, washing machines, doors, windows, and kitchen utensils, it is also used in the handles of contemporary furniture. Additionally, it is used as a trim material for automobiles, railway cars, clamps, trailers, and decorative architecture. However, it is not recommended for any outdoor structural applications due to its susceptibility to crevice and pitting corrosion.

- Grade 201 stainless steel handles are more affordable in general. This is since it possesses a diverse range of mechanical properties. For example, corrosion resistance is comparable to that of grade 304. Apart from handles, it is a common material for catering and kitchen utensils.

304 stainless steel handles

Contemporary stainless steel handles exhibit the following characteristics:

The 304 stainless steel handles are made of chromium-alloyed low-carbon steel. It contains a minimum of 15% chromium and 10% nickel. The presence of chromium alloy provides unmatched and robust corrosion resistance to the accessories.

Stainless steels are rust-resistant in general. They are not, however, immune. Therefore, over time, they will corrode. As a result, routine or holistic cleaning is required to aid in the prevention of corrosion growth. Additionally, it is an excellent method of extending the life of contemporary handles.

Stainless steel has a gleaming, low-maintenance appearance. 304 stainless steel is the most widely used stainless steel grade on a global scale. So it is unsurprising that a large number of homeowners and business owners take advantage of its excellent value and corrosion resistance.

In comparison to 201 stainless steel, it has a chromium content of between 16 and 24 percent. Furthermore, it contains 35% nickel. Additionally, manganese and carbon are present in trace amounts. It is most frequently found in the 18-8 or 18/8 configurations. It contains 18% chromium and 8% nickel.

Another advantage of 304 stainless steel is its resistance to oxidizing acids-induced corrosion. The 304 stainless steel handles are extremely easy to clean as a result. As a result, they are ideal for kitchen use. Additionally, they are being used in increasing interior design, architecture, and site furnishings applications.

There is one disadvantage to 304 stainless steel sheets. It is corrosive to chloride and saline solutions. Corrosion, colloquially referred to as chloride ions can trigger pitting. It is capable of spreading beneath chromium barriers, wreaking havoc on internal structures.

316 stainless steel handles

The second most common type of stainless steel is 316 stainless steel. 316 stainless steel has identical mechanical and physical properties to 304 stainless steel. Indeed, while the two are constructed from similar materials, they remain distinct. Between 2% and 3% molybdenum is contained in 316 stainless steel. As a result, it increases the corrosion resistance of modern handles. Furthermore, it is impervious to industrial solvents such as chlorides.

Apart from modern handles, it is used in various industrial applications requiring a highly saline environment and chemical processing. It is also used in the development of medical-surgical instruments due to its non-reactive properties.

Nickel is used in Type 316 stainless steel sheets to ensure that the composition remains austenitic at low temperatures. Austenitic steels exhibit a wide variety of properties, including strength, resistance to corrosion, and workability. As a result, they are an excellent choice for outdoor architectural and landscape applications.

Modern stainless steel handles are popular because of their exceptional weldability, ductility, and work hardening for spring properties. Additionally, they are hygienic, contributing to the comfort and enjoyment associated with using your cabinetry or other furniture.

Another term for Contemporary Stainless Steel Handles

430 stainless steel handles

This is a rust-resistant modern handle made of grade 430 stainless steel. They are not, however, as good as 304 or 316 stainless steel. They are hygienic, ensuring that your pulls remain clean at all times. They are economical, which enables you to maximize your savings. They are magnetic and intended for indoor use only. In contrast to other grades, they can be exposed to mild chemicals such as detergents and cleaning fluids.

Apart from handles, 403 stainless steel sheets are used in various applications, including drums for washing machines, extraction units, cooker hobs, catering equipment, and hinges.

Our entire product line is constructed entirely of the highest quality stainless steel. We are proud to offer a diverse range of products. Kindly contact us for more information. In addition, our customer service representatives are available and eager to assist and serve you at all hours of the day or night!

Common Applications for Stainless Steel Handles

Due to their durability and functionality, stainless steel handles are used in a wide variety of applications. They are primarily used in a variety of industries’ equipment, including medical, food processing, industrial, automotive, HVAC, outdoor power equipment, farm, and construction machinery.

Stainless steel handles are used on a variety of items, including furniture and appliances.

Take the following into consideration:

- Stainless steel cabinet handles

Cabinets are critical when it comes to customizing your home. They will add to the unique and special appeal of the living space. Additionally, they have a longer shelf life, which translates into financial savings. However, you will be unable to maximize the potential of your cabinet without a durable and aesthetically pleasing stainless steel handle. Stainless steel cabinet handles are the best option. They are an excellent investment that will provide you with long-term happiness.

- Stainless steel refrigerator handles

According to reports, stainless steel handles are used on appliances such as refrigerators. Refrigerator handles made of stainless steel are extremely durable. They are resistant to scratching in the event of an accident and can withstand the commotion of a busy home. In addition, despite frequent and messy use, they will resist rust and staining.

- Stainless steel handles for BBQ grills

Apart from appliances, stainless steel handles are found on a variety of other types of cooking equipment, such as barbecue grills. This is because they are extremely easy to maintain. Cleanup, on the other hand, will be effortless. Spills should be wiped up immediately with a clean rag. Additionally, you can clean it with soap and water. Additionally, some polishes can be used to remove stubborn messes and repel dirt from the surface.

- Stainless steel bathroom handles

One of the dirtiest rooms in the house is the bathroom. As a result, maintaining a clean environment is important. Nevertheless, how? Stainless steel bathroom handles will prove to be extremely advantageous. Even if the improvement is only marginal, it is still beneficial. Stainless steel bathroom handles are resistant to bacteria and germs. These are ideal for households with children and pets but preclude the use of a cleaner. Instead, using a disinfectant solution, sanitize the area and ensure that everyone has access to a safe bathroom.

- Stainless steel handles for cupboards

Stainless steel handles are also used in cupboards due to their neutral appearance. They can add character to a kitchen or a house in general. Whether natural wood cabinets, marble countertops, or stainless steel appliances dominate your space, they can all coexist harmoniously. They have the power to transform an atmosphere into one that is energizing and uplifting.

- Stainless steel door handles

Additionally, stainless steel handles are a popular choice for door handles. We have witnessed the evolution of door hardware over the last few years. Historically, people relied on wood and straightforward doorknobs. The glass doorknob gained popularity around 1910. The design was more ornate and opulent. Finally, metal doorknobs with locking mechanisms became popular

in the latter part of the nineteenth century.

Additionally, stainless steel door handles are available in the modern era. They are durable and robust. Furthermore, they are resistant. The majority of products on the market are chromium-plated, making them more suitable for use in moist environments. As such, they make an excellent door accessory.

- Stainless steel drawer handles

They have an attractive or nickeled appearance, as with other applications. However, due to their design, they are the most sought-after option for many homeowners. Additionally, they are resistant to rust.

- Stainless steel oven handles

Finally, stainless steel handles are included with ovens. They have an aesthetically pleasing or contemporary appearance that other materials do not have. They are durable and will not show signs of wear or damage after years of use. Additionally, they are resistant to water and rust. Additionally, they will undoubtedly enhance the theme of your kitchen.

Shapes for Your Furniture and Appliances

Bow handles are designed to resemble common archery implements. They are easy to use and have a comfortable grip. You will never struggle to open or close your furniture. They have a variety of styles and finishes, ensuring that you will find the perfect fit. Conduct an online search to generate a list of possible matches for your criteria.

Bow handles are designed to resemble common archery implements. They are easy to use and have a comfortable grip. You will never struggle to open or close your furniture. They have a variety of styles and finishes, ensuring that you will find the perfect fit. Conduct an online search to generate a list of possible matches for your criteria.

- Crank-assisted handles

Stainless steel crank handles are frequently used in various applications where optimal leverage from an arm unit is required. We offer crank handles for a variety of industrial products. Each of our solutions is engineered and manufactured to meet or exceed the industry’s most exacting specifications.

Apart from stainless steel, we fabricate crank handles from a variety of other materials. There are options for plastic and aluminum. Numerous of our products come in an array of colors and styles.

- Chest Handles

When it comes to unique pulls, stainless steel chest handles come to the rescue. They are extremely well-engineered and long-lasting. Additionally, they boast an eye-catching design and a small footprint, making them an excellent investment.

By manufacturing stainless steel chest handles, Our company has carved out a unique niche in the industry. Our products are created by a highly productive and adaptable team of professionals. We utilize superior raw materials and state-of-the-art technology.

We test our products against a handle of quality parameters to ensure they are defect-free. Additionally, our valued clients can purchase our products at a reasonable price in a variety of patterns and sizes.

- Recessed handles

A handle is required to operate any door, cupboard, window, fence, or cabinet. Handles are standard, as they have been for centuries in the industry. However, building a new home and replacing doors are not exclusively useful endeavors. It would help if you considered the aesthetic value of your selection. Recessed stainless steel handles are advantageous in this instance.

Recessed handles offer all of the benefits associated with door handles. It is simple to open, close, and operate. Recessed handles are the way to go when it comes to creating a smooth and seamless profile. In addition, they are not inferior to their counterparts in terms of strength. By incorporating them into your door, cupboard, or drawer, you can avoid ineffective protection and early breakage. We take pride in the superior quality of our stainless steel recessed handles, their manufacturing value, and their durability.

We have built a team of adaptable engineers dedicated to providing the best designs over the years. Additionally, we have state-of-the-art manufacturing facilities that utilize the most efficient manufacturing processes and the highest-quality materials. Finally, our customer service team is always available and willing to assist you if you have any questions or concerns! Each member of our staff has a thorough understanding of our product line, including their specifications. In addition, our team is enthusiastic and eager to assist you with any handle-related issues that may arise.

- Handles that are flush with the surface

Here in our company, we flush handles to give your one-of-a-kind designs a clean aesthetic. Our products are entirely constructed of stainless steel, ensuring their longevity. Additionally, the stylish and stunning features of our handles are corrosion-resistant. We offer a more diverse selection of flush handles than our competitors. We provide a range of styles. Furthermore, our solutions are non-corrosive and suitable for use in a wide variety of applications.

- Folding handles

We are a professional manufacturer of folding handles. We are a one-stop shop for anyone looking for custom or stock stainless steel handles.

We keep a large stock of various styles of folding handles on hand to ensure prompt delivery. In addition, we provide prompt quotations for a variety of requirements. Kindly contact us if you are dissatisfied with the handles you currently have. Our products are of superior quality and are reasonably priced.

- Wire-wrapped handles

Untreated brass contains a wire. Additionally, chrome or lacquered finishes are available. Over time, stainless steel wire handles will develop a lovely patina. Our wire handles speak volumes about our craftsmanship. Our artisans possess the necessary expertise and experience to exceed your expectations. Rest assured that we can provide responsive and relevant products for you and your family.

- Handles with Spring-Action

For a more adaptable option, stainless steel spring handles are available. These are incredibly simple to use, and you can carry them comfortably. In addition, they are sufficiently durable to last a lifetime. Due to their eye-catching design, they are also a popular choice among homeowners. Additionally, they are fashionable, forward-thinking, and lovely, all of which you should consider. As a result, why are you waiting? Include spring handles in your shopping list today!

Surface Treatment on Stainless Steel Handles

Successfully utilizing stainless steel is dependent on the grade selected, the surface finish, the environment, the specified maintenance, and the customer’s expectations. Stainless steel handles are extremely resistant to corrosion. However, they will perform poorly in hostile environments. Fortunately, surface finishes can be applied chemically or mechanically.

Understanding how mechanical and chemical treatments affect the surface’s properties ensures that each client receives the best possible outcome. Additionally, chemical treatment is used to improve the performance and aesthetics of corrosion.

Corrosion is inhibited when stainless steel handles are smooth and clean. Being clean entails being free of any contaminants that could be harmful. When left unattended, these can develop crevices and corrosion.

Cleaning the surface of stainless steel with chemicals is a common practice. As a result, the steel surface may become smoother or even rougher. Additionally, it may not affect it. This, however, is process-dependent. Corrosion resistance will significantly improve if the procedure is carried out properly.

The following table summarizes the various types of surface treatments:

- Pruning

Nowadays, the most effective surface treatments are nitric acid and hydrofluoric acid mixtures. Acids come in three different forms: paste, bath, and gel. The commercially available mixtures contain 25% nitric acid and 8% hydrofluoric acid. Unfortunately, both of these chemicals dull or roughen the surface of the material.

Extreme caution is required when working with these chemicals due to environmental and occupational health concerns.

- Privileging

The treatment is available in three forms: bath, paste, and gel. Nitric acid is present in 50% of formulations. They may contain additional oxidizers, such as sodium dichromate, on occasion. Nitric acid treatment must be carried out properly to avoid affecting the aesthetic appearance of stainless steel.

Passivation is most effective when contamination from carbon steel is dissolved from the material’s surface. Additionally, it becomes effective upon the dissolution of sulfide inclusions.

- Electropolymerization

Sulphuric and phosphoric acids are used in conjunction with a high current density to clean and smooth the steel’s surface. The process eats away at the circular valleys and peaks on the surface. Additionally, it increases the surface chromium concentration. Due to its brightness and luster, it can make a significant difference in terms of overall appearance. Roughness varies by only 30%.

- Contamination

The technical term for decontamination is “de-poisoning.” It is a semi-advanced technique that removes all impurities from stainless steel without affecting the material, similar to heat tinting and passive natural layering. As a result, it does not affect the surface roughness of the steel.

Furthermore, decontamination has no adverse effect on plastic or rubber materials. Indeed, it broadens the applicability of the process to high-reliability equipment and the medical industry. Unfortunately, the vast majority of polymers are incompatible with highly acidic oxidants like nitric acid.

The procedure is typically carried out in a weak acid solution, such as formic acid, oxalic acid, phosphoric acid, or nitric acid. This process may take several hours if the impurities are sticky.

Contamination with iron is one issue. Fortunately, steel is impervious to conventional methods of decontamination, such as pickling. Rust is soluble in nitric acid. As a result, a hot solution of phosphoric and citric acid has no effect on it. Metallic iron, on the other hand, is more soluble in nitric acid.

- Experiment with Salt Spray

When purchasing stainless steel handles, you will want to ensure they are of the highest quality. You rely on their grit and tenacity. You want them to be tough enough to withstand harsh environments. Rusted stainless steel handles are a safety hazard and are costly to replace. As a result, manufacturers conduct salt spray tests on their products to ensure their durability.

What Is A Salt Spray Test?

Salt spray testing is a corrosion resistance evaluation procedure used to determine the corrosion resistance of stainless steel, coatings, and other materials used in handle construction. Coatings are used to protect the metal to the greatest extent possible. However, an accelerated corrosive attack will occur during salt spray testing to determine how well the finish protects the metal.

One of the primary goals of the test is to determine the life of the coating.

Effectiveness

Corrosion resistance correlations between expected and observed corrosion resistance are established using stainless steel spray testing. However, the duration of the spray test has a weak correlation with the expected life of the surface coating in practice. This is because external factors heavily influence corrosion.

Spray testing is not a straightforward procedure. This is frequently the case with hot-dip galvanized steel, as drying cycles play a significant role in determining durability.

As a result, the method is most effective when used on samples to determine whether or not a student has passed or failed. Whatever the outcome, it will be compared to the expectations of the audit role. Among other applications, it is used to coat zinc, zinc alloys, phosphate surfaces, copper, chromium, paint coatings, electroplated tin, nickel, and stainless steel.

Why is its use required?

Stainless steel spray testing has long been the de facto industry standard. Given the technique’s speed, low cost, and repeatability, it is unsurprising that it has been used for surface treatment. Testing on an international scale began in 1939. On a global scale, the ASTMB117 is now the most widely used salt spray test. Additionally, it is standardized through a variety of certifications, including ISO 9227.

How does it work?

A spray test is performed in a sealed quality-control chamber to ensure the stainless steel’s accuracy during treatment. A spray nozzle is used to saturate a solution with concentrated saltwater. The saltwater fog is used to create an extremely corrosive environment. After a prolonged period, the appearance of oxides is evaluated.

The more resistant a stainless steel handle is to corrosion, the longer it takes for oxides to form. Typically, testing takes between eight and twenty hours. However, this occurs only when phosphate steel is used. It occurs within 720 hours for zinc-nickel coatings. It will take 1,000 hours to complete the zinc flake surface coatings.

Methods for salt spray testing

All steel-based materials are subjected to a neutral salt spray test using a 5% NaCl solution. Its pH value is between 6.5 and 7.2, which is considered neutral. When it comes to decorative coatings, anodized aluminum, electroplated copper nickel-chromium, and electroplated copper-nickel are all tested using acetic acid combined with copper chloride (CASS) or acetic acid alone (ASS). These have a PH range of 3.1 to 3.3.

The results of a spray test on the corrosion resistance of a coating or material can help you determine whether a particular stainless steel handle is resilient, durable, or long-lasting enough to meet your requirements. Additionally, it will indicate the product’s durability and longevity and the effectiveness with which it performs its function.

Exceptional additional applications

Additionally, the salt spray test can be used to evaluate the following coatings:

- Surfaces containing phosphate (These are pre-treated surfaces with subsequent rust, paint, and lacquer.)

- Zinc allows for plating.

- Electroplated nickel, tin, chromium, and copper

- Non-electrolytically applied coatings (It includes zinc flake coatings.)

- Organic-based coatings (i.e., rust preventives)

- Paint coatings

On hot-dip galvanized surfaces, no salt spray test is performed. It produces zinc carbonates when exposed to a harsh environment. As a result, both the coating metal and the corrosion rate are protected. Zinc carbonates are not formed when a hot-dip galvanized sample is exposed to a salt spray fog.

As a result, the testing method cannot be relied upon to determine corrosion resistance. Visit the ISO 9223 official website for additional information on the guidelines for the proper measurement of corrosion resistance for hot-dip galvanized surfaces.

Conclusion

This concludes our overview of stainless steel handles. If you have been searching for months for the industry’s best service provider, it is time to consider buying from us. We OubeeHandle manufacture handles in a variety of styles, colors, sizes, and shapes for your convenience. Without a doubt, our extensive product selection will assist you in making the best choice.

We have an unmatched commitment to providing solutions that meet your specifications, owing to our decades of experience and extensive industry knowledge. Our employees are talented, adaptable, and sufficiently adaptable to handle your needs. We have the ability to meet or exceed any standard you establish. We are proud of our performance and the business relationships we have with our clients and customers. We make no concessions in product quality or durability, and we take pride in our customers’ satisfaction with our products and services.

Kindly contact us for additional information. You may also contact us via email. Our staff is waiting to assist you! We are available 24/7, and we will respond promptly for your convenience, comfort, and satisfaction! Become a client of ours today to learn more about the services we offer!